Testing

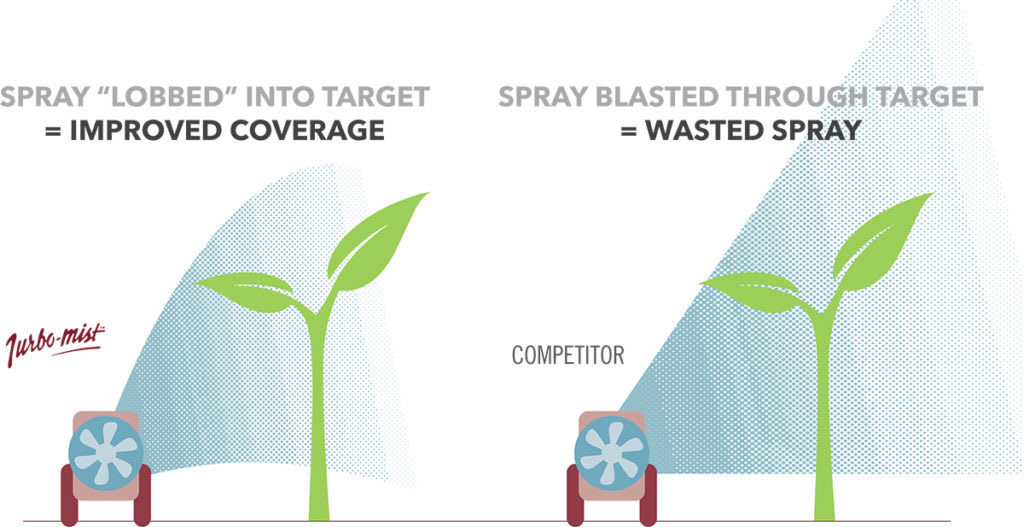

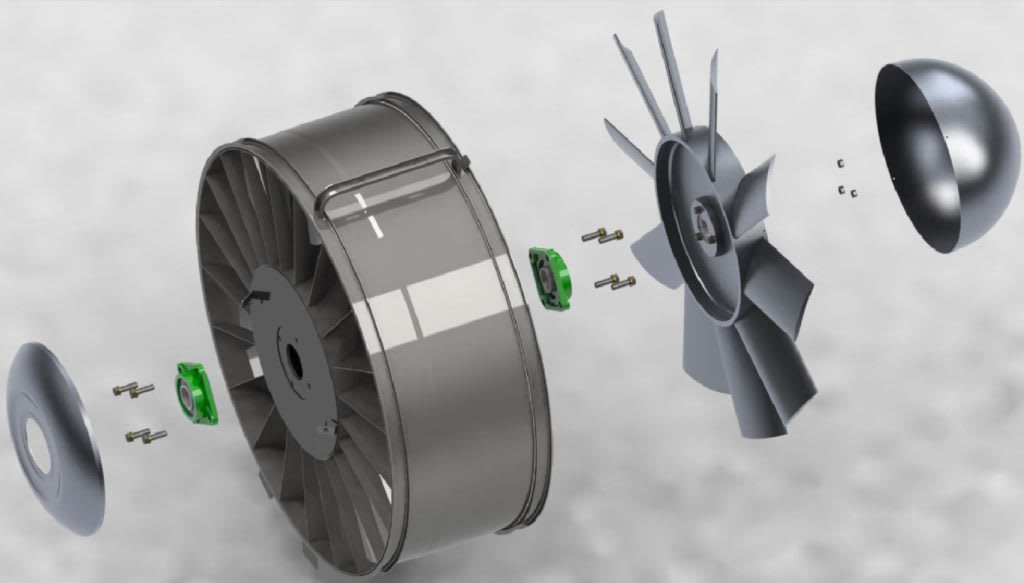

Every Turbo-Mist™ sprayer undergoes rigorous quality assurance testing at each stage of the fabrication process. Our sprayers are dyno-tested to ensure a horsepower output that results in a quieter and more efficient process and vibration analyzed for quality control to ensure maximum reliability in our product. We ensure each component part has been tested to prevent and reduce solution waste, optimize air quality and control, and ensure durability, quality, and consistency.